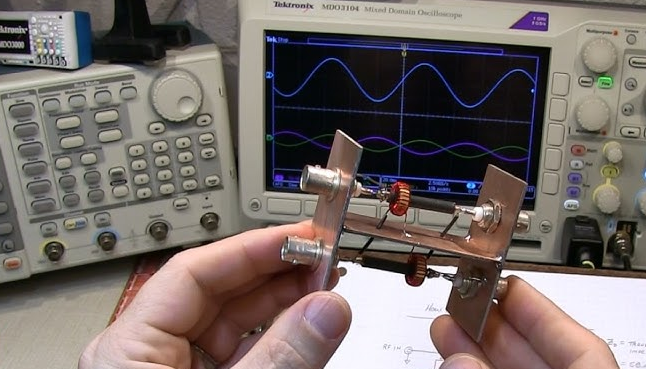

To test a directional coupler, apply a 0 dBm signal and measure key parameters. For instance, verify coupling factor (-20 dBm for 20 dB coupling), insertion loss (-1 dBm for 1 dB loss), and directivity (30 dB if isolated port reads -50 dBm). Ensure all unused ports are 50-ohm terminated.

Verify Coupler Specifications

Testing the directional coupler includes its specification in terms of measurable parameters such as frequency range, coupling factor, directivity, insertion loss, and isolation. A directional coupler that is specified over the range 1 GHz to 5 GHz should have consistent performance over that range. If the signal generator generates a 0 dBm signal at 2 GHz, the power at the coupled port for a 20 dB coupling factor should be approximately -20 dBm. If it is considerably off, such as -22 dBm, the extra 2 dB may be too much insertion loss, and would be a cause for further investigation.

The coupling factor is usually subject to slight variation over the specified frequency range. Manufacturers typically give a tolerance, such as ±0.5 dB. Test of a coupler specified to be rated at 15 dB using a sweep from 1 GHz to 5 GHz could result in a coupling measurement of 14.8 dB at 1 GHz and 15.3 dB at 5 GHz. It is obviously within tolerance. On the other hand, if the measurements indicate 13 dB at some frequencies, then the coupler has a frequency-dependent defect or may be subject to impedance mismatches during measurement. Impedance mismatch can be suspected to exist if, in addition, the return loss is greater than 10 dB at the input port.

Another key parameter is directivity. For this particular directional coupler rated for 30 dB of directivity, the testing comprises the application of a 0 dBm signal at the input port, with the through port being terminated into a 50-Ohm load. For directivity calculation, you can measure the power at the coupled and isolated ports. For instance, if the coupled power measures -20 dBm and the isolated power measures -50 dBm, the directivity is 30 dB, which matches the specification. However, a measured value of 25 dB would suggest insufficient isolation, potentially impacting system performance in applications like signal monitoring or power leveling.

Insertion loss impacts the efficiency of a coupler in signal transmission. A coupler specified for 1 dB insertion loss at 2 GHz to 4 GHz should not have losses much beyond the coupling factor. Measuring a coupler with an input signal of 10 dBm when 9 dBm is measured at the through port assures a 1 dB loss, which is specified; however, if a true measurement is a 3 dB loss, this may be due to internal failures such as degraded components or defects in manufacturing. Testing across frequency range might also show that there is some inconsistency, perhaps 1.5 dB at 3 GHz and 2 dB at 4 GHz, suggesting that there might be frequency-dependent inefficiency.

Use a Network Analyzer

In this respect, a network analyzer can be used for testing a directional coupler, which enables high-precision measurements of the most valuable performance parameters of S-parameters, insertion loss, coupling factor, directivity, and return loss. A good example could be when the coupler works between 1 GHz and 6 GHz, it can be connected to the VNA where a signal applied at the input port. When testing a coupler rated for a 20 dB coupling factor, the VNA should show the S21 parameter (coupled port output) at roughly -20 dB. Deviations, such as -22 dB, may suggest minor losses or manufacturing variations.

Insertion loss is another important factor, where the S21 parameter is measured at the through port. This would mean that if a coupler is rated for a 1 dB insertion loss, the VNA should show about -1 dB when a signal of 0 dBm is applied at the input port. If it shows -1.5 dB, that means there is an extra 0.5 dB loss that could be due to signal path imperfections or connector issues. Sweeping the frequency range of the coupler using the network analyzer can show how insertion loss changes across the operating spectrum, such as -1 dB at 2 GHz, -1.2 dB at 4 GHz, and -1.5 dB at 6 GHz. These changes would point to possible problems with equal signal transmission.

Testing directivity using a network analyzer involves the measurement of the S31 parameter, the signal at the isolated port. A coupling factor of 30 dB implies that for a coupler, there should be very little leakage at the isolated port as long as the through port is terminated in a 50-ohm load. If an input of 0 dBm provides -50 dBm to the isolated port and -20 dBm to the coupled port, the resulting directivity of 30 dB meets the specification. When the isolated port is showing -40 dBm, the directivity drops to 20 dB, which may indicate internal component issues or perhaps inadequate isolation.

Measure Coupling Factor

Measuring the coupling factor of a directional coupler consists of comparing the input power with the power at the coupled port. For instance, injecting a 10 dBm signal to a coupler rated at a coupling factor of 20 dB should approximately read -10 dBm of power at the coupled port. Any deviation, for instance -12 dBm, signals a possible excess loss of 2 dB, due either to frequency-dependent variations or mismatch in the internal constituent parts. This should also be measured over the operating frequency range of the coupler to ascertain that the performance is the same.

In practical testing, the coupling factor can be slightly different at different frequencies. Consider a 15 dB coupling factor-rated coupler operating over the frequency range from 1 GHz to 6 GHz. At 1 GHz, the actual coupling measured can be 14.9 dB, while at 6 GHz it could be 15.2 dB. The above minute variations are usually within ±0.5 dB and well within the allowed tolerance. However, a measure in the actual coupling of 13 dB at 3 GHz points toward a more serious problem that may affect system performance, such as incorrect signal sampling or impedance mismatch.

Accurate measurement of the coupling factor requires termination of all other ports with 50-ohm loads to prevent reflections that would affect the results. For example, a 0 dBm signal injected into the input port of a coupler rated at 10 dB coupling factor at 4 GHz should produce -10 dBm at the coupled port. If other ports are not properly terminated, reflected signals could cause a power level of -8 dBm to be measured and thus provide a false coupling factor of 8 dB, which is not indicative of the coupler performance.

Test Directivity

Assess Frequency Response

Assessing the frequency response of a directional coupler ensures its performance remains stable across its specified operating range. For example, a coupler designed for 2 GHz to 6 GHz must maintain consistent coupling, directivity, and insertion loss throughout this range. Using a signal generator, apply a 0 dBm signal and sweep the frequency incrementally while monitoring the coupled port output. For example, at 2 GHz, the coupling factor can have -20 dBm, and at 6 GHz, it may increase a little, say to -19 dBm, so the frequency response becomes quite flat. However, when at 4 GHz the factor changes to -15 dBm, then this causes potential frequency-dependent variations in the coupler.

Another critical parameter to be tested during the frequency response is the insertion loss. For a coupler rated at 1 dB insertion loss, for example, a signal at 3 GHz might show an output of -1 dBm at the through port, matching expectations. However, at 5 GHz, where the insertion loss increases to 2 dB, it may show design limitations or impedance mismatches at higher frequencies. These measurements outline that insertion loss consistency must be verified through the full spectrum to rule out unexpected degradations in signal in practical applications.

Directivity, too, must be stable through the range of frequency. Starting with a rated directivity of 30 dB for a coupler, testing at 2 GHz could have a coupled port measurement of -10 dBm and the isolated port at -40 dBm to confirm 30 dB directivity. A directivity of 25 dB at 5 GHz—from an isolated port measurement of -35 dBm—could indicate poor isolation at higher frequencies. In fact, performance degradations like this may significantly lower performance in signal monitoring or power division applications.

Check Isolation

Isolation check of directional coupler: It is essential to ensure the minimum signal leakage between input port and isolated port. For example, in a coupler with an isolation rating of 30 dB, the power level at an isolated port should at least be -30 dB of input power. If a 0 dBm signal is applied at the input port, then the power measured at the isolated port should be less than or equal to -30 dBm. In case the measured isolation is -25 dBm, a 5-dB deviation may be attributed to its internal imperfections or due to poor port termination.

Isolation depends on frequency and changes over the operating range of the coupler. Consider a coupler specified for 2 GHz to 6 GHz at an isolation of 30 dB. Testing at 2 GHz could show -33 dBm output from the isolated port for a 0 dBm input; performance, thus, would be better than specification. At 4 GHz, the isolation could decrease to -28 dBm, and at 6 GHz, even further to -26 dBm. These variations imply that the isolation performance at higher frequencies is degrading, which could limit the coupler’s effectiveness in wideband applications.

Isolation testing requires proper port termination. All unused ports should be loaded with 50 ohms to avoid reflections that might interfere with the measurement. For instance, if a 10 dBm signal is injected into the input port, and the coupled and through ports are not properly terminated, then the measured power at the isolated port can increase from -40 dBm to -35 dBm. This 5 dB difference does not reflect the real isolation of the coupler but rather an artifact of poor testing setup.

Examine Insertion Loss

One important aspect of the directional coupler is the insertion loss, which will tell how much power signal is wasted when the signal passes through the main path of the coupler. For instance, if the coupler is rated for insertion loss at 1 dB, then an input signal of 0 dBm should provide -1 dBm output at the through-port. If the measured output is -1.5 dBm, this additional 0.5 dB loss could point to flaws like imperfect impedance matching or poor internal design.

Insertion loss may be different at various operating frequencies for a coupler. Testing of a 2 GHz to 6 GHz-rated coupler with a 1 dB insertion loss may reveal -0.8 dBm at 2 GHz, -1.2 dBm at 4 GHz, and -1.5 dBm at 6 GHz for an input signal that is 0 dBm. While the loss at lower frequencies is minimal, the increasing loss at higher frequencies might reduce performance in applications requiring consistent signal transmission, such as wideband communication systems.

Correct test setup is key to making proper insertion loss measurements. Each of the coupler’s unused ports must be terminated with 50-ohm loads to prevent signal reflections from happening. For example, if a 10 dBm signal is connected to the input port and if the through port is directly measured without appropriately terminating the coupled and isolated ports, then the output could be -8.5 dBm instead of -9 dBm. This would make the insertion loss of the coupler appear larger than it actually is.